If you're here you're probably a fan of steampunk, DIY audio, or hopefully both. I wanted to show off my buddy Greg's absolutely beautiful Steampunk themed Bottlehead Crack. I guess technically you might not be able to call it a Crack anymore given nearly every piece of the kit has been swapped out, but the amplifier section of the circuit the same, a simple tube buffer design.

The Bottlehead Crack has been a popular staple for aspiring DIYers thanks to the lowish price and accessible build. Bottlehead includes step by step directions with pictures so you don't need to know how to read a schematic (although it's fairly easy for tube amps as they are typically simple circuits, so I recommend learning if you can). The stock Crack has very few parts and lacks output transformers so most can complete it in a single evening.

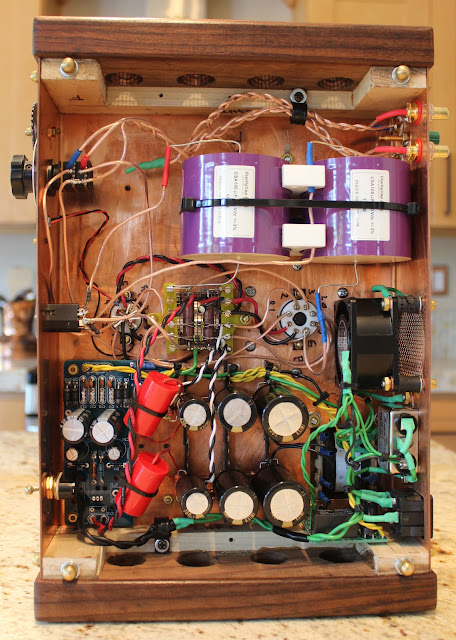

That being said, many users like Greg like to customize their Bottlehead gear, so bespoke wooden bases or unique paintjobs aren't uncommon. Others choose to modify the internals to enhance performance.You will see the frequently replaced electrolytic capacitors with big honkin' film caps. Greg also designed a lovely pair of custom brackets to nestle around the Clarity Caps.

|

| Lots of audiophile goodies inside |

You will see a small power filter near the power IEC socket, then a CRCRC high voltage power filter with Nichicon electrolytics, and near the front switch is a rectifier board. The stock crack has you mount the rectifier circuit on solder tabs around the transformer so this is a nice little improvement. Some people also elect to install ultra-fast diodes as another option. The tube sockets are replaced with the high quality CMC Teflon PTFE sockets which can help dampen tube vibration. These were directly soldered to however you can find PCBs on eBay or AliExpress to make things a little easier. CMC is also now making Bakelite versions of the socket if you are feeling especially vintage.

The stock Alpha potentiometer has been replaced by a higher quality Audio Note version, and Greg let me know he has ample real estate there to mount a larger stepped attenuator. You'll notice this Crack does not have the Speedball upgrade. While the Speedball enhances the performance of the amp as a constant current source for each channel, some people prefer the more "tubey" sound of the stock circuit. I can tell you they are two different flavors and each have their charm. I prefer to mate a Crack with the Speedball upgrade with some warm tubes and a I feel like it's a nice compromise.

While there are plenty of improvements on the inside of the amp, the outside is the bee's knees. You'll see a polished copper chassis adorned with brass acorn nuts, a custom copper heatsink, the obligatory steampunk gears, and an old fashioned double pole knife switch. There is a reason why knife switches have been relegated to Frankenstein films and not household electronics; they are inherently unsafe and can arc when connected to high voltage. A shame as they look bad ass. This one is just for show.

You will also notice there transformer is a little larger above. In fact Greg installed a dedicated heater transformer for the tube heater pins rather than requiring the single transformer from the kit to do all the work.

|

| An earlier version of the unit before the heater transformer was added |

The whole unit is a work of art and has great personality. Despite being Steampunk, there were unique choices. For one much of the copper and brass is shiny and polished vs. aged/scuffed. I think it's great to not force yourself into one line of thinking; make it unique, make it you! Now Greg might have to make a pair of headphones that look equally amazing.

For more steampunk related audio gear, check out this post.

Creator's Bio: Greg Ritacco started mis-wiring audio kits in the 1980's. Gradually fire became smoke and smoke became music. Encouraged by this, Greg briefly pursued a career in audio, first building speakers and later working for Threshold in the "lab". Family pressures and a desire to have his own back yard caused Greg to become more "serious" about his career, and as audio became the stepchild to home theater, and CD's washed vinyl away, Greg gave up and bought a Walkman. These days, he has rekindled his love of LP's and exploding electronics, built a few projects, and he and his daughter share their discoveries of new artists.

Please

remember that building/modifying circuits can be dangerous to you

and/or your surroundings and should only be performed by a certified

technician. The owner of this blog and all associated parties can not /

will not be held responsible if you attempt a build or modification

posted above and cause physical harm to yourself or your surroundings.

Many electronics contain high voltages that can kill, and mods, if

performed improperly, can be a fire hazard.